Any device capable of storing energy is capable of violently releasing it... and electric car batteries are no exception.

To guarantee minimum safety requirements, there is an approval regulation -Regulation 100 CEPE/ONU- that includes a series of tests that must be passed by any high-voltage battery that is mounted in a car. These are minimum requirements, which obviously far exceed the batteries of all currently approved electric vehicles, but which will help us to understand what kind of problems a battery may have to face, what security measures they incorporate to manage them and what can be the worst expected consequences.

In addition, we also review other types of tests that the complete vehicle must pass and the new tests -more demanding- that will be introduced in the future. The bottom line is that batteries are very robust, and reasonably safe...

What tests are performed on the batteries

1. Vibration

The battery is subjected to vibrations of different frequencies –between 7 and 50 Hz- and intensities –from mild to 1 g*– for three hours and in a vertical direction with respect to the battery mounting in the vehicle. This test simulates the rattle during normal driving, and its purpose is to check that the internal components do not move enough to collide with something -low frequencies- nor loosen -the threaded joints-. This test is non-destructive, and the battery should come out of it in good working order.

2. Thermal cycling

The battery is heated and cooled over several cycles. The battery is first placed in a chamber at 60 degrees. Then, it is left at this temperature for six hours and then the temperature of the chamber is reduced to -40ºC in less than 30 minutes… and they wait another six hours. This heating/cooling operation is repeated until a total of five cycles are completed. The battery is then left at room temperature for 24 hours. After all this process, the battery should work normally.

3. External short circuit

How to Maximize Fat Burning During Cardio Workouts - wikiHow: How to Maximize Fat Burning During Cardio Workouts... http://t.co/KGubrtWn

— juliette Tue Dec 20 23:33:59 +0000 2011

It consists of short-circuiting the external terminals of the battery. By uniting positive and negative, we are going to demand almost infinite intensity from the battery. This test tests the internal protections of the battery: fuse and electromagnetic relays or contactors must intervene, cutting the current or limiting it to a safe value, before the battery is damaged. This test may render the battery useless, but it cannot cause leakage, fire, explosion, etc.

4. Mechanical shock

It simulates the deceleration that the battery would suffer as a result of a collision, and tests both the construction of the battery and its anchoring systems to the vehicle. The battery is tested in both longitudinal and transverse directions, reaching a minimum deceleration of 15 G and a maximum of 28 G for a time of at least 120 milliseconds. This test should not be destructive, although the standard does not require that the battery continue to function after the test.

5. Mechanical integrity

The battery is compressed using a specially shaped plate -see photo- to simulate what would happen in a body deformation crash when the body began to compress the battery.

The applied force is 10 tons, and the application time must be less than 10 seconds. This test is destructive - the battery is deformed - but incidents such as sparks, electrolyte leakage, fire or explosion should not occur.

6. Fire resistance

It is the most spectacular test. Take a tray the size of the battery, fill it with fuel and set it on fire. Then, in a first phase that lasts 60 seconds, the battery is brought within 3 meters of the fire. And then the battery is placed over the fire for 70 seconds. After that time, the burning tray is removed, but the battery cannot be touched: if there is something burning -such as plastic connectors- it should be left to continue burning. Obviously, this test is destructive.

The battery may catch fire, but must not explode. By explosion we understand that it bursts with the violent expulsion of gases, flammable liquids or fragments.

7. Over-charge and discharge

We try to charge and discharge the battery beyond what the manufacturer considers recommended, which could damage it and even catch fire. What needs to happen in this test is for the battery management system or BMS to open the contacts to protect the battery. In principle, it should not be destructive.

8. Over temperature

The battery must never be operated at a temperature higher than that specified by the manufacturer as the maximum working temperature.

So the battery is heated to that temperature and it is verified that the internal protections act to open the internal switches of the battery, cutting off the current flow.

You have to lose weight!

And given that lightening the batteries of an electric vehicle is very difficult – they can weigh up to 650 kg – the industry is looking for other formulas: "The weight of an electric vehicle limits its autonomy," explains Ignacio Martín, director of bodywork development at Gestamp, a multinational Spanish of components. “But the fact is that if this factor is reduced in the bodywork –something that Gestamp is achieving, for example, by using aluminum and new welding techniques–, its autonomy is increased and, in addition, its chassis or brakes can be lightened without reducing the security. And it is that there is what we call 'the spiral of weights', by which a reduction in weight in the bodywork can be multiplied by a factor of 1.2; 1.5 - or, in some cases, even by 2 - in the total light weight of the vehicle ».

Checks beyond the battery

In addition to checking the battery, Regulation 100 also requires these other electrical areas to be monitored at the whole vehicle level:

First, it is verified that neither 'direct contact' can occur –that, for example, during maintenance operations, the operator's hand cannot come into contact with any live part–, nor 'indirect' –contact between an electrical component and its housing. The insulation of the high-voltage system is also checked – to ensure that contact with the car body cannot give rise to an electric shock – as well as the marking of casings and cables.

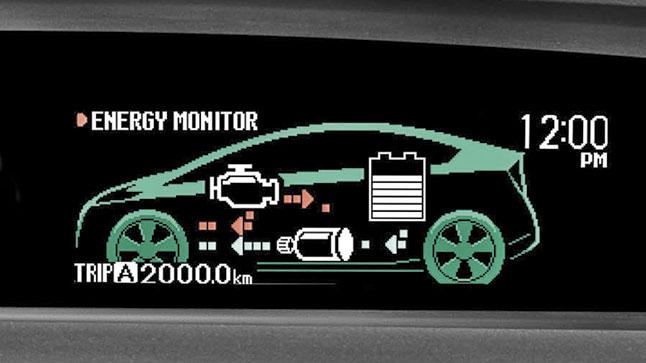

Finally, 'functional requirements' are also verified, such as a warning light on the instrument panel warning the driver that the car is in a position to move, or that it is impossible to start it while the charging cable is connected.

New forms of torture for batteries are coming

At the United Nations, within each homologation area, there are informal 'Working Groups' that continually look at ways to improve and expand the repertoire of tests being conducted.

Currently, the ones that have the most ballots to be incorporated into Regulation 100 are those for penetration -consists of nailing a test device that passes through several cells-, immersion in salt water or propagation -which analyzes what happens to neighboring cells and the entire battery when one of its cells is damaged to the point of overheating, exploding and catching fire.

Spain stagnates in the fight against corruption: the country has spent a decade maintaining its levels in the Corruption Perception Index, which includes the opinion of managers and experts

The 30 best Capable Women's Briefcase: the best review on Women's Briefcase

The daring photo session of Megan Fox and Kourtney Kardashian that causes controversy: They are accused of plagiarism

Become a mystery shopper